Production Bases and Capacity

Delivering products to customers worldwide through a global development and production network

The company spreads its wings to the world as a manufacturer of functional parts for automobiles and motorcycles, developing business from activity bases in the three countries of America, Thailand and China, in addition to three locations in Japan. Each base has its “specialty products” that leverage local strengths and make use of the network mutually to develop production activities of high efficiency. Through this global business expansion, we provide YAMADA products to customers of the world.

Kiryu Department

Address

Kiryu-shi, Gunma

Main products

Transmission hydraulic control parts, half shafts, steering gearboxes

Completed

February 26, 1946

Engineering Department (Equipment Section · Metal Mold Section)

Address

Kiryu-shi, Gunma

Main products

Design and manufacturing of production equipment, jigs, tools, casting molds, and flow measuring devices

Completed

February 26, 1946

Isesaki Department

Address

Isesaki-shi, Gunma

Main products

Oil pumps, water pumps, and electric water pumps for powertrain

Completed

November 1, 1984

YNA - YAMADA North America, Inc.

Address

Ohio, USA

Role

North American base for the production of functional parts for automobiles

Completed

March 29, 1988

YSC - YAMADA SOMBOON Co.,Ltd.

Address

Rayong, Thailand

Role

Southeast Asian base for the production of functional parts for automobiles and motorcycles

Completed

November 29, 1994

YTC - CHENGDU TIANXING YAMADA AUTO PARTS CO., LTD.

Address

Sichuan, China

Role

Chinese base for the production of functional parts for automobiles and motorcycles

Completed

December 19, 1995

YRC - YAMADA R&D CHINA CO., LTD.

Address

Sichuan, China

Role

Research and development into functional parts for automobiles and motorcycles

Completed

April 3, 2006

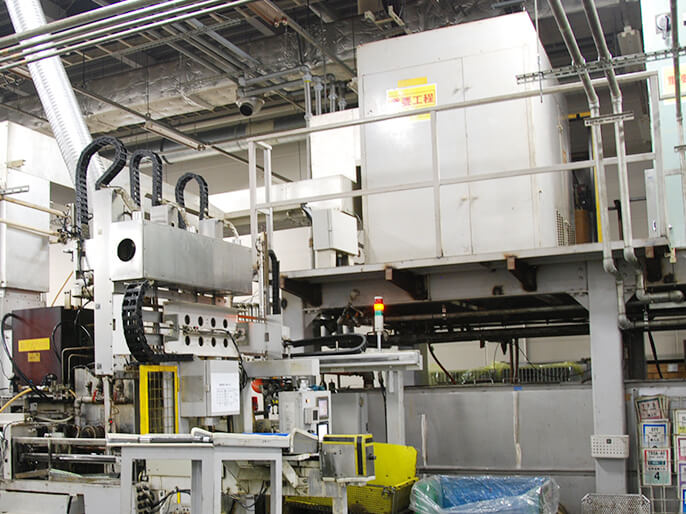

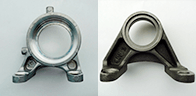

Casting Area

1,650-ton die casting machine 350-ton die casting machine

350-ton die casting machine

5

800-ton die casting machine

1

500-ton die casting machine

13

1250-ton die casting machine

2

600-ton die casting machine

6

1650-ton die casting machine

1

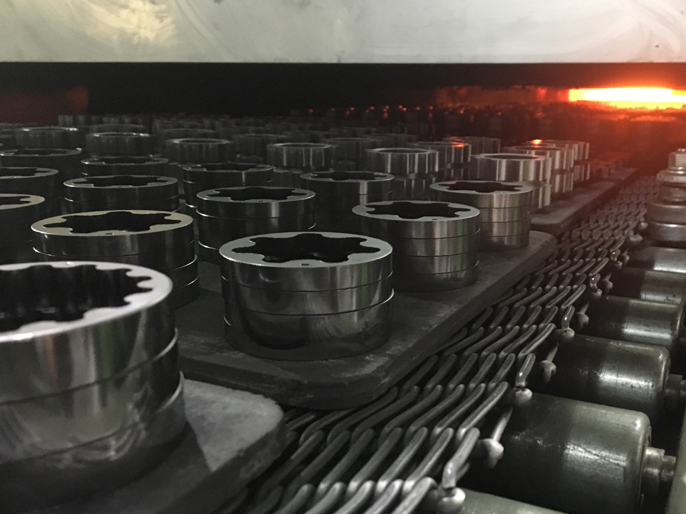

Sintering

Forming Sintering furnaces Recompression (sizing) Machining (CNC lathes/grinding)

Forming presses

4

Recompression presses

4

Sintering furnaces

1

CNC lathes

8

Double-sided grinders

6

Center-less grinders

3

Cylindrical grinding machine

1

Steam furnaces

1

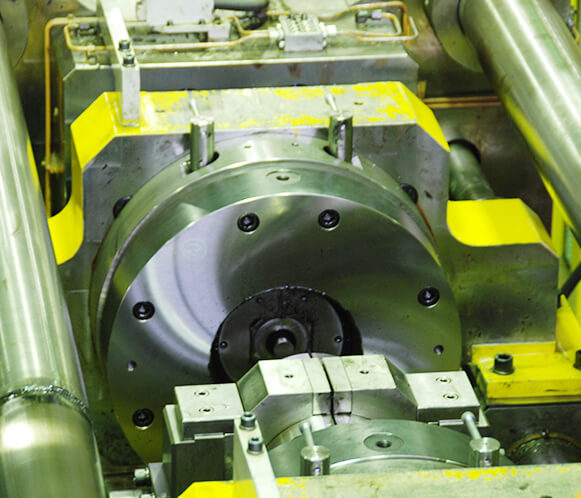

Machining Area

Cutting Induction Hardening Forging Welding

Machining centers

227

CNC lathes(NC lathes)

20

Indexing machines for machining

19

Transfer machines for machining

1

CNC grinders

21

Induction hardening machines

2

Forges

2

Injection molding machines

2

Welders

14

Resin Molding

3

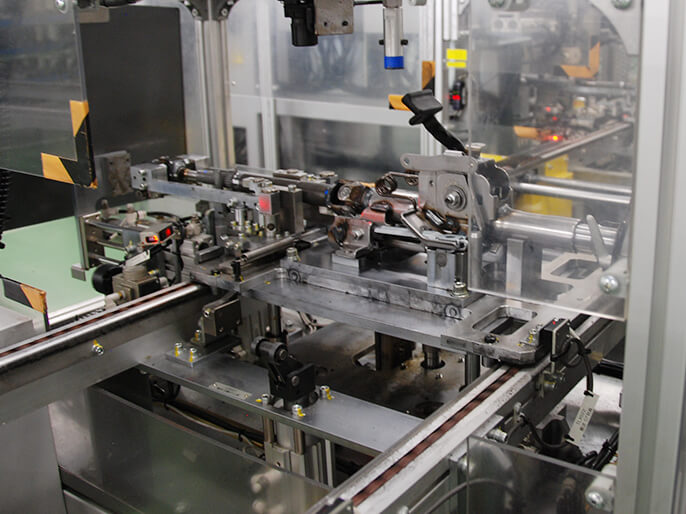

Assembly Area

Oil pump assembly lines

32

Intermediate shafts assembly line

2

Water pump assembly lines

13

Steering gearbox assembly lines

2

Transmission parts assembly lines

8

Brake panel assembly lines

1

Steering column assembly lines

3

Speedometer gears assembly lines

1