- HOME

- Technical Capabilities

- Quality Assurance

Quality Assurance

Quality Policy

YAMADA aims at achieving the quality that surpasses our customer expectation and pre- and post-processes by allowing its employees to exercise their ingenuity through "full participation" and continuously improving work and manufacturing processes and thereby ensuring proper operation of its "Quality Assurance System."

To realize top-class quality, YAMADA mobilizes the capacities of all employees involved in YAMADA products to achieve "Zero-defect" through their "full participation." YAMADA gains customer satisfaction and trust by offering products with the quality that surpasses customer expectation.

Education about Quality

We are focusing on education about quality throughout YAMADA.

In addition to the Quality Assurance System for YAMADA's 3,500 Employees (OFF-JT), as have established a Quality Corner in each plant to provide opportunities for education about quality, where employees can learn while coming into contact with actual products handled on the manufacturing floor and inspection devices. We attempt to enhance quality skills and raise awareness of quality.

Course on quality function

We provide education about quality according to employment position or rank, from new hires to veteran employees, through in-house education programs and external workshops. In particular, we have prepared a program of intensive courses for core personnel and employees stationed overseas. We also encourage employees actively take trade skill tests to further improve their skills.

Class on process FMEA and QA matrix for a new model

The Quality Corner is mainly for members of manufacturing departments. Here we provide education for newcomers and opportunities for employees to learn while coming into real contact with functions, movements, process guarantee methods, and the handling of measurement devices when a new model is being launched. We also provide workshops for improving measurement techniques.

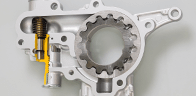

Internal Laboratory

YAMADA has a variety of advanced analytical equipment. Our internal laboratory personnel, who are totally competent, perform numerous types of analyses.

YAMADA's in-house laboratories are located in the each production plant.

Our inspectors perform accurate and speedy tests in-house, from various R&D tests through tests at the prototype stage to tests for mass production quality assurance.

Operation of in-house laboratories and the calibration of testing equipment are conducted reliably in accordance with IATF16949 requirements. Validity is confirmed through internal audits and audits by external audit organizations.

Main testing equipment (we operate more than 200 pieces of large testing equipment)

| Non-destructive inspection devices | Emission spectrophotometers |

| 3-D measuring machines (non-contact and contact types) | Autographs |

| Projectors | Gear testers |

| Climate chambers | Roundness and cylindrical geometry measuring devices |

| Surface roughness and contour form measuring devices | Hardness testers |

| Electronic balances | Salt spray testers |

| Spring testers |

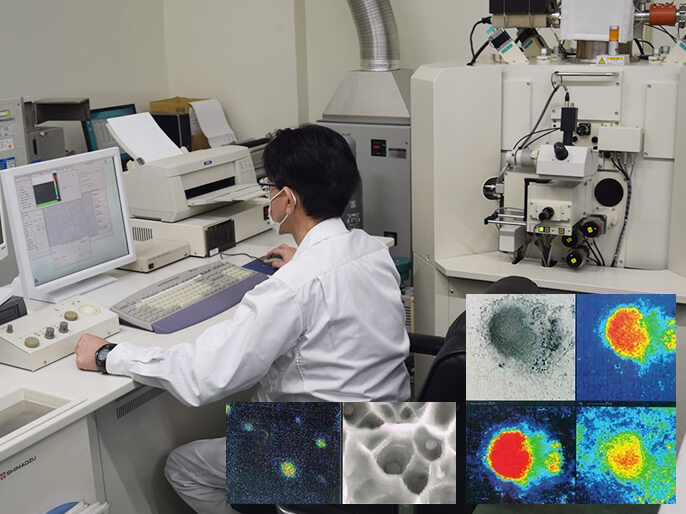

Electron Probe MicroAnalyzer (EPMA)

| Model | Shimadzu EPMA-1610 |

|---|---|

| Electron source | W filament, CeBix cathode |

| Acceleration voltage | 0 to 30 kV (0.5-kV steps) |

| Magnification | 50X to 400,000X |

| Resolution | 5nm |

This analyzer is the most reliable microanalysis device as a scanning electron microscope that clarifies the structural elements of a test piece by exposing it to a proton beam as a non-destructive method of analysis. Moreover, it has a wide field of vision, from the micron level to the order of centimeters, easily enables both observation and analysis, and can perform qualitative and quantitative analyses, chemical bonding state analysis, linear analysis, and provide mapping such as one-dimensional and two-dimensional distributions.

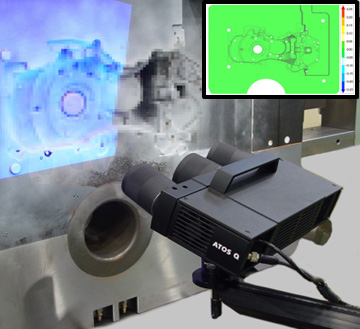

Optical 3D Measuring Systems

| Model | GOM ATOS Q 8M |

|---|---|

| Measurment area 1 shot |

500×370 or 350×260 Switch by lens replacement |

| Accuracy | Error of 0.030 mm or less between 250 mm |

By projecting a fringe pattern (stripe pattern) onto the object to measur and collect the three-dimensional shape of the object with a camera at a high speed of 8 million points per shot, it is possible to enables verification and evaluation of the shape of the product.

By changing the lens, measurement is possible from small objects to large objects such as molds.

International Quality Certification (IATF16949)

All of YAMADA's bases worldwide have acquired ISO/TS 16949 certification, the international standard for quality assurance. We supply products that give customers peace of mind, having been manufactured on production lines with solidly established quality management systems.

| Certified base | Initial certification date | |

|---|---|---|

| YAMADA MANUFACTURING Co.,Ltd. (include the support department, such as design.) | ||

| Isesaki Department | Dec. 27, 2026 | |

| Kiryu Department | Dec. 29, 2026 | |

| YAMADA North America, Inc. | Jan. 25, 2027 | |

| YAMADA SOMBOON Co., Ltd | Jul. 1, 2027 | |

| CHENGDU YAMADA AUTO PARTS CO., LTD. | Aug. 5, 2027 | |

*IATF16949 is the international standard for quality management systems, a specific application of ISO 9001 to the auto industry.